Alright you knuckledraggers, listen up. Since we actually fix our own rigs, and plan on keeping 'em for a long time, let's make 'em easy to fix. That means swapping complexity for simplicity. What we're gonna do today is talk about step one of...um...several in getting the Old Man running right again with a TBI to carb conversion.

And before you idiots in the peanut gallery start spouting off about blah blah EFI is so great, I recommend you step away from your keyboard and actually spin a wrench on your own rig. I know how EFI works, and I'm decently competent at troubleshootin' it. This is exactly why I like removing it from aging vehicles. Notice I said aging, as in NOT NEW, but used significantly. When EFI is new, it's fine. When it isn't new anymore, it's a liability. I cover this in my rant about EFI.

Man...beer is empty. Be right back.

Legal Implications By State

Also, I'd be remiss if I didn't mention the legal side fo this. Some states and counties, occupied by mostly idiots, seem to think they can dictate to you exactly what you can and can not do with your own truck. Some of these hypocritical enviroNazis will frown upon you performing an EFI to carb conversion, and just about anything fun to boot. If you live in a region run by such soulless bipedal water bags, I suggest you confirm with your local laws as to whether this will put you on the wrong side of the boys in blue. Thankfully, I live in an area devoid of such moronic statues of cronyism. If you're unsure, check anyway. Alright, I've warned ya, carrying on.

Damn. Empty again. This article is gonna require a few barley brain cells. Where was I? Oh yeah.

Step 1: Fuel Delivery

In the example I'm gonna give here, we're gonna swap a Holley Truck Avenger 470 and HEI distributor on my plow rig. It's a very early Dodge TBI setup on a trusty 318 from the late 80s. A ton of this will translate to the similar vintage, and excellent GM trucks, as well as Fords. Step 1 entails finding out what the hell you got on the fuel side (spark is rather straightforward) and what it'll take to get it moving without a handful of sensors just waiting to ruin your day. Let's look at the fuel side of things.

- We got a fuel tank, that one is pretty straightforward. It holds fuel, noodlehead.

- We got a fuel pump and regulator, more on this below.

- We got a filter. Just like your coffee, you don't want chunks of something other than fuel in your fuel.

- Two lines of various size: a source and a return line.

Note: Some trucks won't have a return line. If you don't, you'll need to make one. I won't be covering that in this article. Maybe if I do a 2nd gen Dodge carb conversion on my other truck, I'll talk about that part.

The primary goal of Step 1 is to get your fuel source set to the pressure you need it to be. Most TBI systems require a fuel pressure in the teens or low 20s PSI. This is generally way too high for a carb. Holley recommends between 5 and 7 PSI. The key is to get the right kind of pressure regulator in place to drop the PSI to a level perfect for the carb we're using.

Holley recommends between 5 and 7 PSI

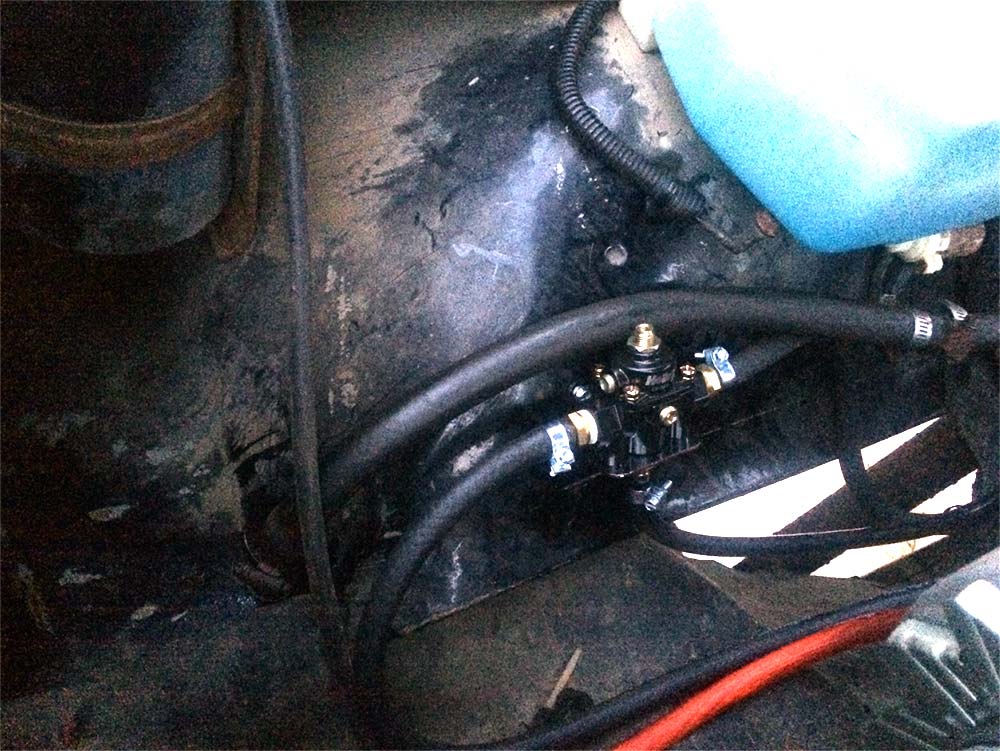

Since the OEM regulator is not only incorrectly set for what we want, it's not adjustable, and it's built into the TBI module itself. And since all that garbage is being thrown out, we'll need to source a new regulator. Thankfully Holley makes one for exactly this kind of swap, and it's preset to their ideal desired pressure of 6 PSI.

I decided to run all new lines in a separate project but you don't need to. All you need to do is mount the regulator in a safe spot, on the fender worked well and run the source and return lines to the ports labeled on this unit.

Buying Hardware Sucks

Lemme take a minute to add this tidbit. Buying hardware sucks, and it's gotten quite expensive. I buy a ton of stuff online these days, but I'd avoid buying this online as it's almost always twice as much as it is locally, unless you buy it by the crate. Plus, if you get it locally, you can doublecheck it's the right thing.

Also, you may need different fittings based on your year or make/model. Before you take anything apart, measure the ID (inside diameter) of your hoses and go get extra hose and some barbed fittings from your FLAPS (friendly local auto parts store). Mine were 3/8ths barb to 3/8ths NPT.

Testing Fuel Pressure

While you're at the FLAPS, you may be able to rent a Fuel Pressure Test Kit for free. Since I'm not the trusting type, I rented one to confirm the regulator was preset correctly. Here's how to test fuel pressure:

- After you get the regulator mounted, and the lines hooked up and clamped down tight, hook up the test unit and plug the end where the carb will be.

- Turn the truck to Accessory, which should start the pump running, and go check your PSI. Mine was dead on at 6 PSI.

Mission Accomplished

We have the PSI we need and we didn't hack apart the truck to do it. We're now ready for another beer...um...I mean Part 2.